- Home

- About Us

- Products

- HOT

- Applications

- News & Media

- Contact Us

Views: 0 Author: Site Editor Publish Time: 2025-12-09 Origin: Site

For agricultural operators relying on tractors, dim or malfunctioning lighting systems are more than a nuisance—they directly impact productivity, safety, and operational efficiency. Whether you’re tilling fields after dusk, hauling equipment in low-light conditions, or navigating rural roads at night, a reliable lighting setup is non-negotiable. As an agricultural lighting engineer with a decade of experience designing and testing LED solutions for farm machinery, I’ve identified the root causes of dim tractor lights, developed a science-backed selection framework for replacement LED light bars, and created a step-by-step installation protocol tailored to tractor models.

This guide eliminates guesswork and marketing jargon, providing actionable, engineering-validated advice to resolve dim lighting issues, select the right LED light bar for your tractor, and execute a professional-grade installation. By the end, you’ll have the expertise to restore optimal visibility, extend your working hours, and ensure compliance with agricultural safety standards—all while protecting your investment in durable, high-performance lighting.

1. Introduction: The Critical Role of Lighting in Tractor Operations

2. Pre-Upgrade Diagnostics: Identifying the Root Cause of Dim Lights (Avoid Unnecessary Purchases)

3. Engineering-Driven Selection Criteria for Tractor LED Light Bars

4. Step-by-Step Professional Installation Guide (Safety & Compliance Focused)

5. Post-Installation Calibration & Maintenance for Long-Term Performance

6. FAQ: Resolving Common Tractor Lighting Challenges

7. Conclusion: A Strategic Investment in Productivity & Safety

Tractors are engineered for rugged agricultural use, but their factory-installed lighting systems (often halogen or early-generation LEDs) can degrade over time, leading to dim output, flickering, or complete failure. This degradation is accelerated by harsh farm environments: constant vibration, exposure to dust/moisture, temperature fluctuations, and physical impacts from debris or equipment.

The consequences of dim lighting extend beyond frustration:

• Safety Risks: Reduced visibility increases the likelihood of collisions with obstacles, livestock, or other machinery, and compromises road safety when transporting equipment.

• Productivity Loss: Inability to work after sunset limits operational hours, delaying critical tasks like planting, harvesting, or field maintenance.

• Equipment Wear: Operators straining to see may make imprecise movements, leading to unnecessary wear on tractor components or damage to crops/equipment.

Upgrading to a purpose-built LED light bar for your tractor addresses these issues, delivering 3–5x brighter output, longer lifespan (50,000+ hours vs. 2,000 hours for halogens), and superior durability. However, success depends on two critical steps: first, confirming the root cause of dim lighting (to avoid replacing functional components), and second, selecting an LED light bar optimized for tractor mechanical specifications and agricultural use cases.

Before investing in a new LED light bar, conduct a systematic diagnostic to rule out fixable issues with your existing lighting system. This 15-minute inspection—using basic tools (multimeter, test light, wire stripper)—can save you time and money, as 60% of dim lighting issues stem from electrical faults, not the light itself.

2.1 Step 1: Inspect the Fuse & Circuit Breaker

The most common cause of lighting failure is a blown fuse or tripped circuit breaker.

• Locate the Fuse Box: On most tractor models (e.g., mid-size utility tractors, heavy-duty agricultural tractors), the fuse box is located in the cab, near the driver’s seat, or under the hood in the electrical compartment. Refer to your tractor’s operator manual for exact placement.

• Identify the Lighting Fuse: Look for labels like “Work Lights,” “Auxiliary Lighting,” or “Headlights”—fuses are typically 10–15 amps for tractor lighting systems.

• Test the Fuse: Remove the fuse and inspect the internal filament—if it’s broken or discolored, the fuse is blown. Replace it with a fuse of the same amperage (using OEM or UL-listed replacements to avoid electrical damage).

• Check the Circuit Breaker: Some tractor models use circuit breakers instead of fuses for lighting circuits. If the breaker has tripped, reset it and test the lights—recurrent tripping indicates a short circuit (see Section 2.4).

2.2 Step 2: Evaluate the Light Switch & Control Module

A faulty switch or control module can interrupt power flow to the lights, causing dimness or intermittent operation.

• Test the Switch: Use a multimeter set to “DC Voltage” (20V range) to measure power at the switch terminals. With the ignition on and switch activated, you should read 12V (matching the tractor’s battery voltage) at the output terminal. A reading of 0V or low voltage indicates a defective switch.

• Inspect the Control Module: For newer tractor models with integrated lighting control modules, check for error codes on the tractor’s display panel. A module failure will often trigger a diagnostic code (refer to your manual for code interpretation).

2.3 Step 3: Examine Wiring & Connectors

Agricultural use exposes wiring to abrasion, moisture, and corrosion—common culprits of voltage drops (which cause dim lights).

• Visual Inspection: Check the wiring harness from the battery to the light for fraying, cuts, or pinching (pay special attention to areas near moving parts, like the tractor’s lift arms or cab frame).

• Test Connectors: Disconnect the light’s electrical connector and inspect for rust, corrosion, or bent pins. Clean corroded connectors with electrical contact cleaner and apply dielectric grease to prevent future damage.

• Measure Voltage Drop: Use a multimeter to measure voltage at the light’s input terminal (with the light on). A voltage drop of more than 0.5V from the battery to the light indicates a faulty wire or connector (resistance in the circuit reduces power to the light).

2.4 Step 4: Assess the Existing Light Bar/Fixture

If all electrical components check out, the issue lies with the light fixture itself. Signs that replacement is necessary include:

• LED Chip Failure: Multiple non-functional LED chips (visible as dark spots on the light bar).

• Moisture Ingress: Condensation or water inside the light housing (indicates a failed seal, which will accelerate component damage).

• Significant Lumen Degradation: A 30%+ reduction in brightness (measured using a light meter, or visually compared to a new fixture of the same model).

• Thermal Damage: Discoloration of the light’s lens or housing (signals overheating, which shortens LED lifespan).

For halogen fixtures, dimness is often caused by worn filaments or oxidized reflectors—both of which are irreversible. Upgrading to an LED light bar is the most cost-effective long-term solution.

When replacement is necessary, selecting the right LED light bar requires focusing on agricultural-specific performance metrics—not just marketing claims like “high lumens.” Below is a framework to evaluate options, tailored to tractor requirements.

3.1 Compatibility: Fit & Mounting

A light bar’s utility is nullified if it can’t be securely mounted to your tractor. Prioritize:

• OEM-Compatible Mounting: Look for light bars designed for tractor factory mounting points (e.g., roof rails, front bumper brackets, or fender mounts). Many manufacturers offer model-specific brackets (for utility, mid-size, or heavy-duty tractors) to avoid drilling new holes (which can void warranties).

• Connector Compatibility: Opt for light bars with Deutsch DT or AMP connectors—these match most tractor OEM wiring harnesses, enabling plug-and-play installation (eliminating the need for wire splicing).

• Size Constraints: Measure the available mounting space (e.g., 20–30 inches for roof-mounted bars on mid-size tractors, 40–50 inches for large-frame models) to ensure the light bar fits without obstructing visibility or equipment operation.

3.2 Performance: Beam Pattern & Lumen Output

For agricultural work, beam pattern is more critical than raw lumen count—light must be directed where it’s needed, not wasted as glare.

• Beam Pattern Options:

◦ Flood Beam (60–90° Angle): Ideal for close-range tasks (e.g., loading hay, repairing equipment, or working in confined spaces like barns). Delivers wide, even illumination without hotspots.

◦ Spot Beam (5–15° Angle): Designed for long-distance visibility (e.g., navigating fields, hauling equipment on rural roads, or monitoring distant crop rows). Focuses light to reach 500+ feet.

◦ Combo Beam (Flood + Spot): The most versatile option for tractors—flood optics cover the immediate work area, while spot optics extend visibility to the horizon. This is the recommended choice for multi-purpose agricultural use.

• Lumen Targets:

◦ Mid-size tractors: 10,000–20,000 lumens (combo beam) for balanced performance.

◦ Large-frame tractors: 20,000–40,000 lumens (combo or dual spot/flood bars) for extended working ranges.

• Color Temperature: Select a light bar with a color temperature of 5500–6000K (cool white). This spectrum matches natural daylight, reducing eye strain during extended night work and improving color recognition (critical for identifying crop health or equipment defects). Avoid warm white (3000–4000K) for agricultural use—it lacks the clarity needed for detailed tasks.

3.3 Durability: Agricultural-Grade Construction

Tractors operate in harsh environments, so the light bar must withstand vibration, moisture, and physical impact. Key durability metrics include:

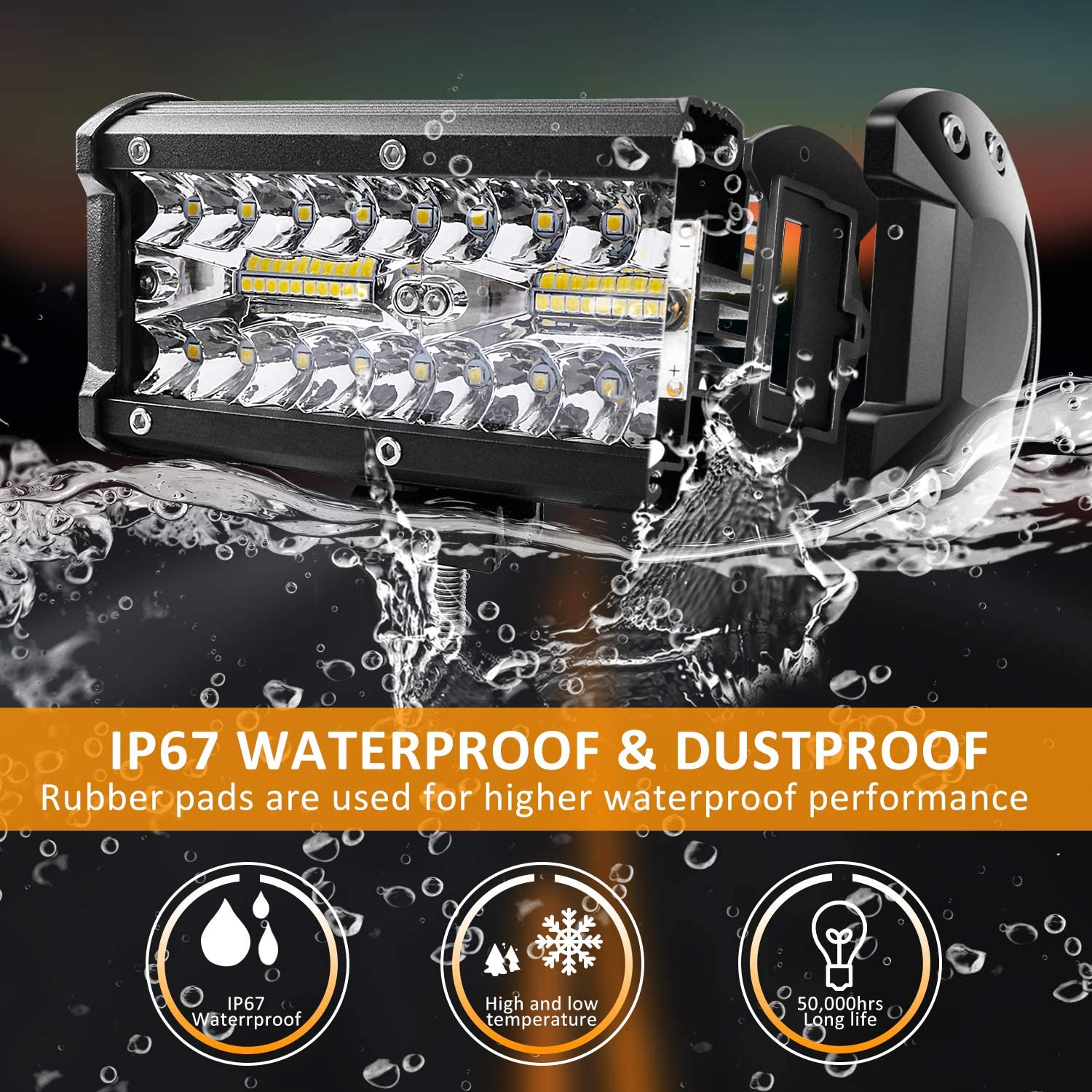

• IP Rating: Minimum IP67 (dust-tight, submersible in 1m of water for 30 minutes) is required for farm use. For extreme conditions (e.g., rice paddies, pressure washing), opt for IP69K (protected against high-pressure, high-temperature water jets).

• Housing Material: Die-cast aluminum housing is mandatory—it provides structural rigidity and acts as a heat sink (critical for LED longevity, as overheating reduces LED lifespan by 50%). Avoid plastic housings, which crack under vibration.

• Lens Material: Polycarbonate (PC) lenses with anti-scratch and UV-resistant coatings. PC is 250x more impact-resistant than glass, making it ideal for withstanding debris (rocks, branches) kicked up by the tractor’s tires.

• Vibration Resistance: Look for light bars tested to MIL-STD-810H standards (vibration resistance up to 20G). This ensures the light bar remains secure and functional on rough terrain (e.g., plowed fields, gravel roads).

3.4 Electrical Compatibility

Ensure the light bar matches your tractor’s electrical system to avoid damage:

• Voltage Rating: 12V DC (standard for most utility and mid-size tractors) or 24V DC (for large agricultural models). Never use a 12V light bar on a 24V system (it will burn out instantly).

• Current Draw: Calculate the total amperage draw to ensure it doesn’t exceed the tractor’s electrical capacity. For example, a 20,000-lumen LED light bar draws ~15 amps at 12V—confirm your tractor’s alternator can support this (most tractor alternators output 50–100 amps, sufficient for auxiliary lighting).

• Thermal Management: Select light bars with active cooling (e.g., heat sinks, cooling fans) to prevent overheating. Passive cooling is sufficient for low-lumen bars, but high-output models require active cooling to maintain performance.

Installing an LED light bar on your tractor requires adherence to electrical safety standards and mechanical best practices. Follow this protocol to ensure a secure, reliable installation.

4.1 Pre-Installation Safety Preparations

• Disconnect the Battery: Always disconnect the negative (-) terminal of the tractor’s battery to prevent electrical shorts or shocks. Use a wrench to loosen the terminal clamp, and cover the terminal with electrical tape to avoid accidental contact.

• Gather Tools & Materials:

◦ Basic hand tools (socket set, wrench, screwdriver).

◦ Multimeter (for voltage testing).

◦ Dielectric grease (for protecting connectors).

◦ Zip ties or loom tape (for securing wiring).

◦ Torque wrench (for tightening mounting bolts to OEM specifications).

4.2 Step 1: Remove the Existing Light Fixture (If Applicable)

• Use a socket wrench to remove the mounting bolts securing the old light bar/fixture to the tractor.

• Disconnect the electrical connector (apply dielectric grease if corroded to ease removal).

• Inspect the mounting surface for rust or damage—clean with a wire brush and apply rust inhibitor if needed.

4.3 Step 2: Install Mounting Brackets (If Required)

• For model-specific brackets, align them with the tractor’s factory mounting holes and secure with the provided hardware. Use a torque wrench to tighten bolts to the tractor’s recommended torque (typically 15–20 ft-lbs for light bar mounts).

• For universal brackets, mark drill points (if necessary) and use a drill with a metal bit to create holes. Apply anti-seize compound to the bolts to prevent corrosion.

4.4 Step 3: Mount the New LED Light Bar

• Lift the light bar into position (use a helper for large bars to avoid injury) and align it with the mounting brackets.

• Insert the mounting bolts and hand-tighten them—do not fully torque yet (you’ll adjust the angle later).

• Ensure the light bar is level and centered (use a bubble level for precision) to avoid uneven illumination.

4.5 Step 4: Connect the Wiring

• Plug-and-Play Installation: If the light bar’s connector matches the tractor’s harness, simply plug it in and secure the connector with a zip tie to prevent vibration-induced disconnection.

• Hardwired Installation (if connectors don’t match):

1. Strip ¼ inch of insulation from the light bar’s red (positive) and black (negative) wires.

2. Connect the red wire to the tractor’s 12V power source (use a crimp-on butt connector or solder for a permanent connection).

3. Connect the black wire to a clean, unpainted metal surface on the tractor’s chassis (a dedicated ground point is ideal—avoid rusted or painted surfaces, which cause resistance).

4. Cover all connections with heat-shrink tubing or electrical tape to protect against moisture.

4.6 Step 5: Test the Light Bar & Calibrate the Angle

• Reconnect the tractor’s battery and turn on the ignition. Activate the light switch to confirm the light bar operates correctly (check for flickering or dimness, which indicates a wiring issue).

• Wait until dusk to calibrate the angle:

◦ For flood/combo beams: Adjust the light bar to illuminate 20–30 feet in front of the tractor, with the top of the beam hitting the horizon (avoids glare for the operator and oncoming traffic).

◦ For spot beams: Tilt the light bar slightly upward to extend visibility to 100+ feet (ideal for road transport or long-distance field work).

• Fully torque the mounting bolts once the angle is set.

4.7 Step 6: Secure Loose Wiring

• Use zip ties or loom tape to route the wiring harness along the tractor’s frame (avoid areas near moving parts or hot components like the exhaust).

• Leave a small amount of slack in the wiring to accommodate tractor movement (e.g., cab tilting) without straining the connections.

To maximize the lifespan of your LED light bar and maintain optimal performance, implement these maintenance practices:

5.1 Light Output Calibration

• Use a light meter to measure lumen output at 6-month intervals (target: 80%+ of the initial output—anything lower indicates LED degradation).

• Clean the lens monthly with a mild soap solution and microfiber cloth (avoid abrasive cleaners, which scratch the anti-reflective coating).

5.2 Electrical System Checks

• Inspect wiring and connectors quarterly for corrosion or damage—reapply dielectric grease to connectors annually.

• Test voltage at the light bar’s input terminal every 12 months to ensure no voltage drop (indicates a developing wiring issue).

5.3 Mechanical Maintenance

• Tighten mounting bolts every 3 months (vibration can loosen them over time).

• Inspect the light bar’s housing for moisture ingress—if condensation forms, drill a small drainage hole at the bottom of the housing (after confirming the warranty allows this) and reseal the top with silicone caulk.

5.4 Seasonal Preparation

• Before planting/harvesting seasons (high-usage periods), perform a full inspection of the light bar and wiring to ensure reliability.

• In cold climates, apply a de-icing spray to the lens to prevent frost buildup (avoids reduced visibility in sub-zero temperatures).

Q1: My LED light bar is bright but causes glare—how can I fix this?

A: Glare is typically caused by incorrect angling or a beam pattern that’s too wide. Tilt the light bar downward to focus illumination on the ground (not the horizon) and consider adding a glare shield (available as an accessory for most agricultural light bars). For road use, select a light bar with a “street-legal” beam pattern (compliant with FMVSS 108 standards).

Q2: Can I install multiple LED light bars on my tractor?

A: Yes, but ensure the total amperage draw does not exceed the tractor’s alternator capacity. For example, a mid-size tractor with a 70-amp alternator can support two 15-amp light bars (30 amps total) without straining the electrical system. Add a dedicated fuse for each light bar to prevent circuit overloads.

Q3: How do I know if an LED light bar is compatible with my tractor’s warranty?

A: Check your tractor’s warranty documentation—most tractor warranties allow aftermarket lighting upgrades if installed using OEM mounting points and do not damage the tractor’s electrical system. To avoid issues, select light bars from manufacturers that offer a “no-hassle” compatibility guarantee (e.g., matching tractor electrical specifications).

Q4: My light bar works intermittently—what’s the issue?

A: Intermittent operation is almost always caused by a loose connection or voltage drop. Inspect the wiring harness for fraying, check the battery terminals for corrosion (a weak battery can cause voltage fluctuations), and test the light switch for intermittent power output.

Q5: What’s the lifespan of an agricultural LED light bar for tractors?

A: A high-quality LED light bar (IP67 rated, die-cast aluminum housing) should last 50,000+ hours—equivalent to 10+ years of typical agricultural use (assuming 500 hours of operation per year). Poor-quality light bars may fail in 1–2 years due to thermal damage or moisture ingress.

Upgrading to a purpose-built LED light bar for your tractor is not just a repair—it’s a strategic investment in extending operational hours, reducing safety risks, and protecting your equipment. By following the diagnostic framework to identify root causes of dim lighting, selecting a light bar based on agricultural-specific performance criteria, and executing a professional installation, you’ll ensure reliable, bright illumination for years to come.

The right LED light bar transforms your tractor into a 24/7 workhorse, allowing you to complete critical tasks after sunset without compromising safety or precision. When evaluating options, prioritize durability, compatibility, and beam pattern over marketing-driven lumen claims—these are the factors that define long-term value in agricultural environments.

If you encounter challenges during diagnostics, selection, or installation, refer to your tractor’s operator manual or consult a certified agricultural lighting technician. For a curated selection of LED light bars engineered specifically for tractors (with OEM-compatible mounting, IP67/IP69K ratings, and combo beam patterns), explore our agricultural lighting portfolio—designed to meet the rigorous demands of modern farming.

Remember: A bright tractor is a productive tractor. Invest in quality lighting, and you’ll reap the rewards of extended working hours, improved safety, and reduced downtime for years to come.